適用材質: 碳鋼板、不銹鋼板、鋁板、銅板、鈦合金、有色金屬、橡塑材料、大理石、石墨等。

工件類型: 各類平面板類零件。

| 參數項目 | 詳細指標 |

| 設備型號 | SMYJ - RRW1000 |

| 加工寬度 | 1000mm (可定制) |

| 加工厚度 | 1 - 80 mm |

| 升降方式 | 四柱式同步升降 (數字化設置) |

| 砂帶線速度 | 18 m/s (可選變頻調速) |

| 拋光輪線速度 | 20 m/s (可選變頻調速) |

| 輸送速度 | 2 - 11 m/min (變頻可調) |

| 配套設備 | 濕式吸塵機 或 工業(yè)脈沖吸塵機 |

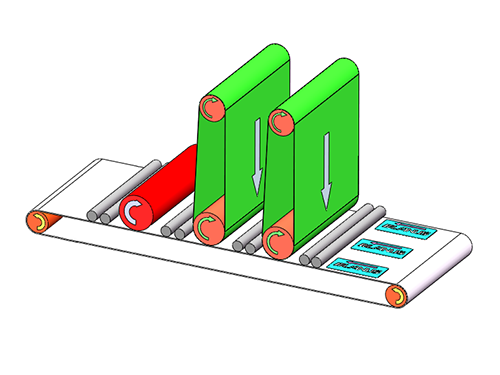

| 設備組合 | 二道寬幅砂帶+拋光輪(可定制) |

根據工件材質和尺寸,提供多種送料方式:

輸送帶 + 橡膠壓輥夾送: 適用于普通工件 (長度 ≥ 280mm)。

強力永磁吸附: 適用于碳鋼類工件 (尺寸 ≥ 10mm x 10mm)。

真空負壓吸附: 適用于不銹鋼、銅、鋁等非磁性工件 (尺寸 ≥ 50mm x 50mm)。

橡膠滾輪 + 橡膠滾輪夾送: 適用于大型、重型工件 (長度 ≥ 280mm)

|  |